What Is an Automation Control Panel and Why Does It Matter in Electrical Projects?

Introduction

If you’ve ever wondered how complex electrical systems operate with minimal human input, the answer often revolves around one key component: the automation control panel. As the command centre for electrical operations, these panels are the driving force behind smooth-running machinery, streamlined workflows, and intelligent energy management.

As Singapore advances its smart nation goals to promote smart electrical infrastructure, automation control panels are becoming vital across all building types. Once limited to factories and commercial facilities, these panels are now increasingly used in residential developments to manage lighting, HVAC, energy usage, and home automation systems.

This article explains what these panels are and how they work. We also explore why they matter to anyone involved in designing or managing modern electrical projects.

Key Takeaways:

What Role Do Automation Control Panels Play in Modern Systems?

Automation control panels act as the command centre for controlling machinery, electrical equipment, and building systems. They play a part in improving efficiency, safety, and automation across various sectors.

What Types of Automation Panels Are Available?

Standard panels suit basic applications, while custom panels are designed for complex projects that require scalability and integration with platforms like PLC, SCADA, or IoT.

What Are the Core Components That Make Automation Control Panels Work?

Components like PLCs, HMIs, I/O devices, relays, and power supplies collectively enable automated control, real-time monitoring, and safe operation.

How Do Automation Control Panels Benefit Electrical Projects in Singapore?

They enhance energy efficiency, support EMA-compliant electrical works, enable remote access, and align with sustainability initiatives like the BCA Green Mark.

What Should You Look for in an Electrical Contractor for Automation Projects?

Choose a provider with proven experience in PLC panel integration, licensed electricians, knowledge of electrical work in Singapore, and the ability to deliver end-to-end solutions.

Overview of an Automation Control Panel

What Is an Automation Control Panel?

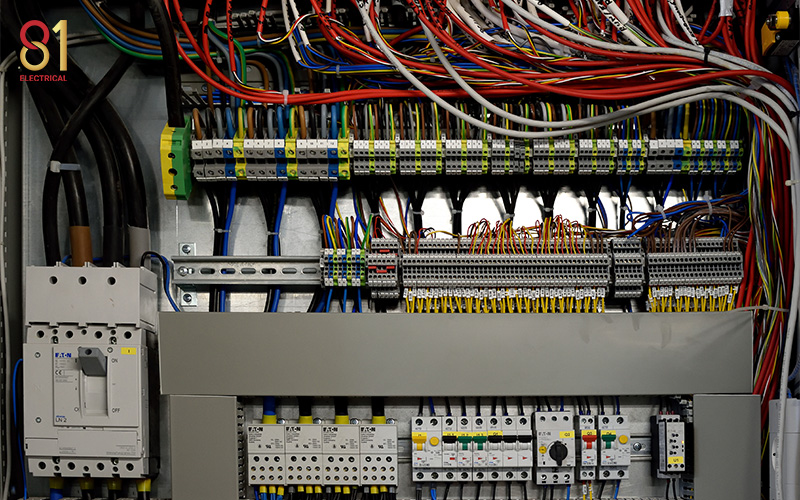

An automation control panel is the nerve centre of any automated electrical system. Designed to monitor, manage, and control equipment, it plays a part in ensuring smooth, efficient, and safe operations across various applications. These panels consolidate control over multiple electrical devices and processes, reducing human intervention while improving overall system performance.

What are the Common Types of Automation Control Panels?

1. Standard Control Panels

These are pre-engineered solutions designed to handle common control requirements such as managing lighting circuits, simple machinery, or HVAC systems. They are cost-effective, quick to deploy, and easy to integrate, making them ideal for small-scale applications where advanced customisation isn’t required.

2. Custom Control Panels

Custom control panels are tailored to meet specific project requirements, taking into account factors such as environmental conditions, system complexity, and integration with platforms like SCADA, PLC, or IoT systems. Featuring high flexibility, scalability, and performance optimisation, they are well-suited for complex applications in manufacturing, utilities, infrastructure, and energy sectors.

What Are Their Key Functions?

Automation control panels perform a wide range of functions central to modern electrical systems. By enabling seamless integration between hardware, software, and sensors, automation control panels serve as intelligent hubs that monitor, regulate, and optimise operations across various environments. They ensure that systems run efficiently, safely, and with minimal human oversight.

1. Automate Processes

Automation control panels execute pre-programmed logic to run machines and systems with minimal manual input. They help improve consistency and precision in operations.

2. Improve Productivity

By streamlining workflows and reducing the need for manual intervention, these panels significantly enhance operational efficiency. They execute tasks with speed and consistency, minimising downtime and ensuring that processes run smoothly from start to finish.

3. Enhance Safety

Built-in safety features such as overload protection, emergency stops, and fault indicators are critical for maintaining safe operating conditions. These mechanisms detect abnormal conditions early and trigger immediate responses to prevent equipment damage or system failure.

4. Support Smart Infrastructure

Integrated with modern monitoring tools and communication protocols, control panels enable real-time data collection and adaptive control. They have become essential for energy-efficient, connected buildings in line with Singapore’s Smart Nation vision.

What are Their Core Components?

After understanding the key functions of automation control panels, we now turn to the components that make these systems work. Each part plays its role in enabling precise control, real-time monitoring, and seamless automation.

The effectiveness of a panel depends on the performance and integration of these core elements:

1. Programmable Logic Controllers (PLCs)

Often considered the brain of the system, PLCs execute logical operations based on input from connected sensors and devices. These ruggedised computers are designed to withstand industrial environments and are programmable to suit a wide range of control scenarios. Thanks to this flexibility, they can be deployed for everything from HVAC control to fully automated production lines.

2. Human-Machine Interface (HMI)

The HMI is the visual and operational gateway between the human operator and the control panel. It can be as simple as a series of push buttons or as advanced as a full-colour touchscreen displaying live process data. Through the HMI, operators can monitor system status, make adjustments, and receive alerts promptly.

3. Input/Output Devices (I/Os)

These serve as the panel’s eyes and hands. Input devices include sensors that gather information such as temperature, pressure, or flow rate. Output devices, such as relays or motor starters, act on PLC commands to control equipment. Together, they allow the electrical control system to interact dynamically with its environment.

4. Relays and Contactors

Relays are electrically operated switches used for low-power control tasks, while contactors are more robust and capable of switching high-current loads. These components handle the physical switching of circuits, enabling safe and efficient activation of motors, lighting, or other equipment based on PLC instructions.

5. Circuit Breakers and Fuses

Safety is non-negotiable in any electrical system. Circuit breakers and fuses protect the panel and its connected systems from overloads and short circuits. Breakers can be reset after tripping, whereas fuses must be replaced once blown. Both are critical to preventing electrical hazards and ensuring personnel safety.

6. Power Supply Units

These units convert incoming AC or DC power to the specific voltage required by the control panel’s internal components. Apart from voltage conversion, they stabilise the power supply to prevent fluctuations that could damage sensitive electronics.

How Automation Control Panels Work

Now that we’ve identified the key components of an automation control panel, let’s look at how these elements come together to create a fully functioning control system. The operation of a panel follows a structured flow, from detecting conditions in the environment to executing decisions and providing real-time feedback:

1. Signal Reception and Sensor Input

The process starts with input devices and sensors gathering data from the environment or connected machinery. These could measure variables like temperature, pressure, speed, or proximity. The collected data is then transmitted to the PLC for processing.

2. Control Logic and PLC Execution

Once inputs are received, the PLC runs its pre-programmed control logic. It analyses the incoming data and determines the appropriate actions. These include activating a motor, opening a valve, or issuing a warning signal. This logic can be simple or highly complex, depending on the system’s needs.

3. Output Control and Activation

After processing the control logic, the PLC sends output signals to devices like relays, contactors, or motor starters. These components then execute physical actions, such as powering a conveyor belt and adjusting ventilation.

4. Real-Time Monitoring and Feedback

The HMI displays system status and performance metrics in real time, allowing operators to monitor activity and intervene when needed. In more advanced systems, this data can also be accessed remotely through SCADA platforms or cloud-based dashboards, enabling off-site control and predictive maintenance capabilities.

The Role of Automation Panels in Electrical Projects

Why Automation Panels Matter in Electrical Projects

Automation panels are redefining how electrical systems operate by boosting the efficiency of every electrical project. From smart factories and commercial complexes to integrated infrastructure, these panels pave the way for smarter and more responsive networks.

1. Improved Efficiency and Productivity

Automation panels enable round-the-clock process automation, minimising the need for manual operation and significantly reducing the risk of human error. By integrating PLC panel systems, these setups ensure that operations run smoothly with real-time responsiveness and logic-based control. They can be a major driver in manufacturing plants and high-output environments.

2. Enhanced Safety

In Singapore, conducting EMA-compliant electrical works is a legal requirement. Equipped with fault protection features, emergency shut-off mechanisms, and real-time diagnostics, automation control panels help maintain workplace safety. They incorporate features such as overload protection and fault detection, promoting system integrity and keeping consistent operation within regulatory limits.

3. Energy Management

With increasing focus on sustainability, automation panels help optimise energy usage across lighting, HVAC, and production systems. When integrated into building automation solutions, they support initiatives like the BCA Green Mark Scheme by enabling smart scheduling, peak load management, and energy consumption tracking.

4. Remote Monitoring and Control

Modern control panels often incorporate IoT technology or SCADA systems, allowing facility managers to monitor and manage systems remotely. In mission-critical environments such as data centres, smart factories, and automated commercial buildings, uninterrupted operations are non-negotiable. With remote monitoring, issues can be identified and addressed almost instantly, minimising disruptions and enabling predictive maintenance strategies.

5. Scalability and Integration

One of the most valuable advantages of automation panels is their flexibility. From initial electrical panel installation in Singapore to future upgrades, these systems are easily scalable and adaptable. Expanding a commercial space or upgrading an industrial plant? Integrate automation panels with your existing infrastructure to make way for future enhancements.

What to Look for in an Electrical Contractor for Automation Projects

Choosing the right electrical contractor is crucial to the success of any automation-driven project. A qualified partner performs proper installation and guarantees long-term system performance at the same time.

Keep these in mind when selecting a reliable electrician in Singapore:

1. Automation Expertise

Look for contractors with a proven track record in PLC panel integration and custom control panel design. Deep knowledge in building automation solutions and programming ensures the system is tailored to your specific operational needs.

2. Licensed and Safety-Compliant

Partner with a contractor who employs certified electricians familiar with EMA-compliant electrical work. This ensures that your project adheres to Singapore’s strict electrical safety codes, thereby preventing costly rework and potential legal issues.

3. Local Knowledge

An experienced local team understands the nuances of electrical work in Singapore, including inspection procedures, submission requirements, and statutory regulations. This insight reduces project delays and streamlines the approval process.

4. Turnkey Solutions

For hassle-free execution, engage a contractor that provides turnkey electrical solutions. Benefit from their expertise in initial design, electrical panel installation, system testing, and maintenance. A dependable power electrician with end-to-end capabilities can help future-proof your automation project while maintaining long-term system health.

Frequently Asked Questions

1. What’s the difference between a distribution board and an automation control panel?

The former distributes electricity to various circuits, while the latter actively manages and automates the performance of electrical systems. It is programmable and interactive, enabling smarter operations.

2. How long does it take to design and install an automation control panel?

The timeline depends on the complexity of your project. Simple control panels may take a few days, while fully customised systems with PLC programming and HMI integration could take several weeks. An experienced electrical contractor will assess your requirements and provide a realistic project schedule.

3. Can automation panels be integrated with IoT or smart building systems?

Yes. Most modern automation control panels can be integrated with IoT devices, building management systems (BMS), or SCADA platforms to enable real-time data tracking, remote access, and predictive maintenance.

Conclusion

As Singapore advances toward a more connected and sustainable infrastructure, electrical projects that integrate intelligent automation will be better equipped to meet evolving demands. Automation control panels are at the heart of this transformation.

Driving efficiency, enhancing safety, and enabling smarter operations, they align data-driven operations with the nation’s push for innovation and energy optimisation. Let 81 Electrical help you stay ahead. As a reliable electrical company in Singapore, we are committed to delivering EMA-compliant electrical work.

From periodic inspections to prompt issue resolution, our electrical services in Singapore are carried out by licensed electricians with deep industry experience. Looking to upgrade your automation and electrical setup?

Contact us today.